Founded in 2014 by brothers Chris and Jason Angelini, American Bench Craft set out to redefine leather goods in America. Seeking to find satisfaction in an honest day’s work, their mission was to manufacture top-quality leather products that are designed to withstand the rigors of everyday hard use. Comprised of family and friends, the brothers got to work in their parents’ garage and American Bench Craft was born. We had the opportunity to ask them a bit more about their story.

Tell us a bit about the brand. Where did it start and what was the vision behind starting it?

It all started with a simple leather wallet, featuring riveted construction, designed to never fall apart. With no business plan or any source of funding, we found ourselves working out of our parent’s garage with a long road ahead. We were our first customers. Then we sold products to our family and friends, who told their family and friends, and before we knew it, we had a business. Through the support and loyalty of our customers, American Bench Craft has been able to steadily grow year after year. Based on our customer’s feedback and input, we have expanded our product line to include belts, wallets, coasters, bags and more.

What’s the story behind the brand’s name? Has the name “American Bench Craft” helped the brand live up to its mission?

American Bench Craft was the name we came up with because it summarizes our mission to create a true American manufacturing company. Our company stands in direct contrast to automated machine-made products, typically made cheaply and outsourced from overseas labor.

Our skilled American workforce handcrafts products at workbenches with a sense of care and pride. This sentiment in our company’s vision ensures our products are built to withstand everyday hard use – no matter the lifestyle.

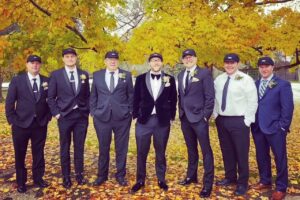

Photo provided by Leah Angelinii

Your products are ethically and sustainably made, what is American Bench Craft’s hope for striving towards quality goods?

All of our products and materials are sourced and made in the USA at our workshop in Wilmington, MA. We have a small but dedicated team that carefully makes each product by hand, quality checks by hand, and ships by hand. This process ensures our involvement at every level of product, and helps us to produce the highest level of quality when entering and leaving our workshop. We combine unique designs, sturdy, high-quality materials, and reliable American craftsmanship to offer leather products that truly stand the test of time.

Like Stormy Kromer, you make your products by hand. What are some of the biggest challenges you’ve faced as a hand-made leather goods business?

After coming from an engineering background, Jason does all the designing and prototyping at our workshop. The design process is almost always inspired when we see a common theme emerge from customer requests. This makes for a more motivating design process. We know that once we perfect the product, we already have customers ready to enjoy it. We usually test a design for at least a couple of months before having the tooling made. As we’ve scaled, we’ve learned that even simple processes are prone to quality control issues and you can’t underestimate the importance of stringent quality control processes. Human error is unavoidable, and rather than trying to avoid it, we identify it quickly and reliably to minimize waste and ensure every product we send out the door meets our standards.

How have partnerships, such as the one you have with Stormy Kromer, reflected your desire to serve a broader community?

It’s an honor working with other production companies in America such as Stormy Kromer, because the unfortunate reality is that American manufacturing has been dwindling for decades. Mass consumption, coupled with companies moving overseas, has flooded the market with cheap products that end up in landfills. We still believe that American manufacturing is the best in the world, and that’s how we find value in partnerships with companies like Stormy Kromer. At the end of the day, we are both striving to serve our customers with quality rather than quantity.

Photo provided by Leah Angelinii, featuring the American Bench Craft Bill-Fold Wallet

What impact do you hope your products have on your customers on a local level?

Without our local customers, American Bench Craft wouldn’t be where it is today. We were featured on Made In Mass back in 2022 and the response we got from local customers was unbelievable! We’ve recently started doing more local fairs, like the Topsfield Fair in Massachusetts. Serving our local community, it’s great to be able to talk to our local customers in person and develop that personal relationship with them.

Beyond the Product: The American Bench Craft Way

Through a craft manufacturing approach and a vertically integrated business model, American Bench Craft takes great pride in serving its customers, employees, and community. American Bench Craft manufactures all of its products in-house and manages its own shipping and fulfillment, customer service, marketing, and sales operations. This streamlined approach has allowed founders Jason and Chris to build a company and brand with which they are intimately connected. Through their commitment to local production and sustainable practices, Jason and Chris have created more than just a leather goods company – they’ve built a community dedicated to timeless quality and authentic connections. As American Bench Craft continues to grow, it remains rooted in its founding principles, inviting customers to be part of a story where every stitch, rivet, and handshake matters.